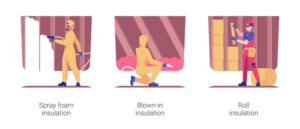

The Different Types Of Insulation Available

Insulating your home is one of the most cost-effective ways to reduce your energy bills and create a greener environment. There are many different types of insulation available, from blanket batts to blown-in insulation made from recycled newspaper, cellulose, and fiberglass.

The best choice will depend on your climate, the part of your house you’re insulating, and your budget. The following four options are some of the most popular Insulation Tulsa choices:

Spray Foam

Spray Foam

Spray foam insulation (SPF) is an alternative to traditional insulation materials such as fiberglass or cellulose. It is sprayed on the roof of a building or in wall cavities and expands as it hardens, creating an air seal that minimizes air infiltration. It is commonly used in new construction projects and commercial structures. It is also an effective option for insulating older homes.

Two liquid chemicals (isocyanate and polyol resin) combine at the tip of a special spray gun to form SPF. The chemical reaction happens very quickly, forming the SPF within seconds. The spray gun is then attached to the SPF mixture and is applied to a surface, such as the inside of a wood-framed wall.

The foam then dries, creating an effective air and vapor barrier in the space being insulated. There are a couple of different types of SPF insulation: open and closed cells. Open-cell insulation has a porous cell structure that allows air to move through it, but it still creates an effective barrier against air movement and sound. It is typically more flexible and less rigid than closed-cell foam, and it can be sprayed on existing walls without damaging the drywall. It can absorb moisture and vapor, however, so it must be used in conjunction with a vapor barrier.

Closed-cell foam has a more compact cell structure and a higher density than open-cell foam, and it is more rigid. It is a good choice for wood-framed walls and can be used in the attic or other open spaces. It is not recommended for the walls of new houses, but it can be used in addition to fiberglass or cellulose in old homes. It is a good choice for pole barns and other outdoor structures, as it provides excellent protection against weather.

It is important to note that only properly trained and certified contractors should apply spray foam insulation. Improper application can lead to extensive and costly damage, including rotted framing and toxic mold. Many unscrupulous contractors are pitching this product to unknowledgeable homeowners as a quick, easy, and affordable way to cut their heating bills while failing to disclose its risks. If you choose to use this insulation, look for brands that offer low GWP blowing agents.

Cellulose

Cellulose insulation is made from recycled paper fiber that is blown into wall cavities to help insulate, draughtproof, and reduce noise transmission. It is the most commonly used type of insulation in new homes and is also a popular option for retrofits in old buildings. It has high draught-proofing and thermal properties, as well as an excellent rating for sound reduction. It can be installed at various thicknesses, depending on the building and the homeowner’s needs.

Most cellulose is produced from either mechanical or chemical pulp and is often mixed with inorganic fire retardants to ensure it meets safety standards. It can have a low flame spread and smoke developed index, which is very important in the event of a house fire, as it limits the amount of dangerous, toxic smoke inhalation. It is also non-combustible, and can resist the penetration of fires through walls, windows, doors, and electrical wires.

The cellulose used for insulation is usually sourced from post-consumer recycled newsprint and is treated with a combination of chemicals including boric acid and borax to reduce the risk of mold and insect infestation. This makes cellulose a very eco-friendly choice, especially when compared with other insulation materials such as fiberglass which contain high percentages of petrochemicals. The cellulose insulation manufacturers’ association claims that insulating one home with cellulose will recycle as much newspaper as the average person consumes in 40 years.

Loose-fill cellulose can be installed at different densities and is available under a variety of brand names. It is generally considered to be the most durable form of cellulose and requires little maintenance or upkeep once it has been correctly installed. However, a poorly installed cellulose can lose R-value over time and may become subject to moisture intrusion which will lead to rot, mold growth, or damage to the structural integrity of the roof or walls.

Loose-fill cellulose is blown into walls using a blowing machine and can be applied to the inside or outside of the frame of the building. It can be affixed between the studs and the framing and is typically applied to all areas of the walls including the attic space. The loose batting can also be stuffed into a cavity behind an existing drywall to help seal air leaks around the window, door, and electrical openings.

Mineral Wool

Mineral wool, also called stone or rock wool, is a durable and sustainable option for insulating homes. It’s made from a mix of natural stone fibers, molten volcanic rock, and steel slag (a waste product from making steel) and is typically comprised of 90% recycled content. It has a higher R-value than fiberglass and is moisture resistant, which helps prevent mold and mildew. It’s also more fire-resistant than other types of insulation. Mineral wool will not burn until it reaches about 1,800 degrees Fahrenheit, meaning it acts as a fire barrier and slows down fires in homes, giving firefighters more time to save lives and property. This type of insulation is not without its drawbacks, however. Mineral wool contains a formaldehyde binder to glue the fibers together, and this can be problematic for homeowners who are sensitive to this chemical. The good news is that the process that manufactures mineral wool uses removes most of the free formaldehyde, so this type of insulation has lower levels than fiberglass.

Another downside of mineral wool is that it can be difficult to install if you’re not used to working with it. Unlike cellulose, which can be easily blown in by a machine, mineral wool needs to be cut and shaped to fit in a wall cavity. Builders use a bladed knife or saw to cut the material into pieces that are large enough to fit into studs and meet specifications. This is an additional cost, but it may make sense for those seeking more sustainable options than fiberglass when undergoing a major home renovation.

Like cellulose, mineral wool can be installed in both framed and SIP walls. It’s often combined with drywall to provide more energy-efficient and soundproof homes. It can also be added to floors in addition to walls and ceilings to improve acoustic performance.

Because of the dense and sturdy nature of rock wool, it is a good choice for filling hard-to-reach places in the wall, such as outlets, pipes, and other obstacles that can be difficult to measure accurately with a roll of fiberglass batts. It’s so dense that you can even carve it to fit around outlets and other obstructions in the walls.

Loose-Fill

Loose-fill insulation, also known as blown-in insulation or cellulose insulation, is very versatile and can be used in new construction or existing homes. It can be installed on walls and attics. It has an R-value of about 3.5 per inch of thickness, which is significantly higher than fiberglass insulation. Blown-in cellulose is typically made from recycled paper products such as shredded newspaper and cardboard boxes. Cellulose insulation is a sustainable product, and it can help homeowners save energy costs by keeping their homes warmer in the winter and cooler in the summer. It is not as expensive as other insulation products, and it provides many other benefits to homeowners as well, such as fending off vermin and insects and reducing noise in the home.

Blown-in cellulose is often installed in attics by using a blower machine with an electric motor and rotating teeth or prongs that fluff up the cellulose and spray it into the attic or wall cavities. It is also often installed in new construction houses by injecting it into empty walls, under the framing, or inside studs. It is usually done with a special nozzle that shoots the cellulose in varying lengths and diameters. After the cellulose has been applied, it is often dampened with a mist of water that helps to set the material into the walls. This dampening process is important, as the cellulose must be moist enough to stick permanently and not too wet, which can lead to mold problems.

After the cellulose has been dampened, it is sometimes stabilized with borate chemicals. These chemicals prevent the cellulose from absorbing as much water and thereby becoming less effective. Stabilized cellulose is often used in wall cavities, while unstabilized cellulose is normally used in attics.

In addition to the water, some loose-fill insulations are mixed with other chemicals to provide fire retardancy and other properties. The most common chemicals are boric acid, sodium borate (borax), and ammonium sulfate. These chemicals are typically added to the cellulose during manufacturing.

Loose-fill insulation can be a health risk for anyone who works with it, so proper safety equipment should be worn. This includes eye protection, a respirator, long-sleeved shirts, pants, and gloves.